GM Automotive oil pumps

Introduction to GM Oil Pump

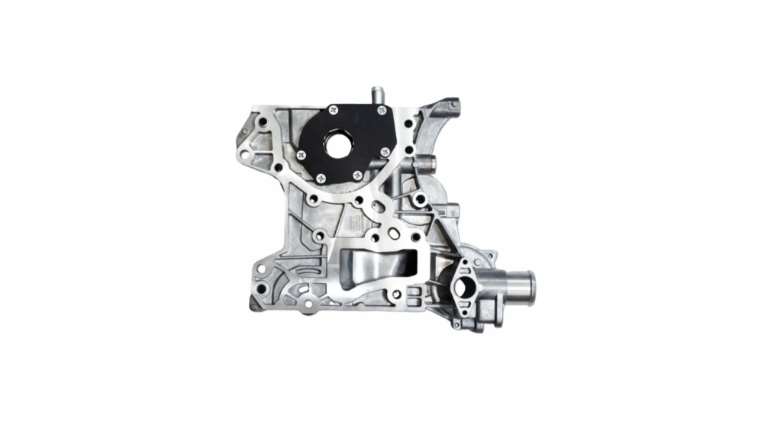

The GM oil pump is a critical component of the engine lubrication system. Its primary function is to circulate the engine oil to ensure proper lubrication of all moving parts within the engine.

The GM oil pump is typically driven by the engine's crankshaft or camshaft, depending on the engine design. It consists of a housing, gears or rotors, and an internal pressure relief valve.

The housing encloses the gears or rotors, providing a sealed environment and preventing oil leaks. The gears or rotors rotate within the housing, drawing oil from the oil pan or sump through a suction tube. As the gears or rotors turn, they create pressure within the pump, which forces the oil to flow through the engine's oil passages, lubricating the crankshaft, camshaft, connecting rods, and other critical engine components.

The GM oil pump also incorporates an internal pressure relief valve. This valve is designed to open at a predetermined pressure, allowing excess oil to flow back into the oil pan, preventing an over-pressurized system. This helps maintain a consistent oil pressure within the engine, ensuring optimal lubrication under varying conditions.

GM oil pumps are designed and manufactured to meet stringent quality standards and provide reliable performance. They undergo rigorous testing to ensure durability and efficiency. Additionally, regular maintenance and timely replacement of worn or damaged oil pumps are essential to maintaining the longevity and efficiency of the engine.

In conclusion, the GM oil pump plays a vital role in the engine lubrication system. It ensures proper oil circulation and lubrication of all moving parts, preventing engine wear and damage. With their high-quality design and manufacturing, General Motors oil pumps are a reliable choice for maintaining optimal engine performance.