Introduction to Diesel Engine Oil Pump

In the realm of diesel engines, the oil pump plays a crucial role in ensuring their smooth operation and longevity. This article will provide a comprehensive introduction to diesel engine oil pumps, focusing on their significance and functionality. With the keywords "diesel engine oil pump" at the foreground, this professional blog post aims to enlighten and educate readers about this vital component.

1.What is a Diesel Engine Oil Pump?

A diesel engine oil pump is an integral part of the lubrication system in a diesel engine. It circulates oil to various engine components, ensuring efficient lubrication, reducing friction, and preventing wear and tear. An optimal oil pump is vital for maintaining engine performance, efficiency, and durability.

2. Functions of a Diesel Engine Oil Pump:

a) Oil Circulation: The primary function of the oil pump is to circulate oil throughout the engine, ensuring all moving parts are properly lubricated. It helps deliver oil to the bearings, camshaft, crankshaft, pistons, and other critical engine components.

b) Lubrication: The pump ensures a continuous supply of oil to reduce friction between components, minimizing heat generation and prolonging engine life.

c) Cooling: Oil also plays a vital role in dissipating heat from the engine. The oil pump ensures proper oil flow, which aids in cooling crucial engine parts, such as pistons and cylinder walls.

d) Filtration: Some oil pumps have built-in filters to remove contaminants from the oil, preventing damage to the engine and maintaining oil cleanliness.

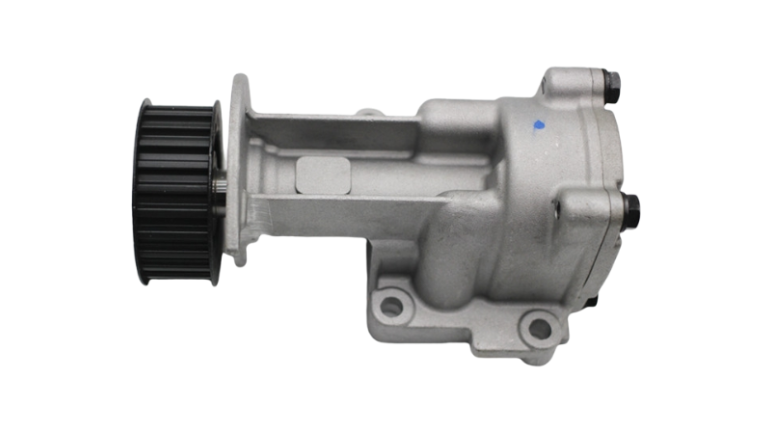

3. Components of a Diesel Engine Oil Pump:

a) Drive Shaft: The drive shaft connects the oil pump to the engine. It is usually driven by a gear, chain, or belt, deriving power from the engine's rotation.

b) Rotor Set: The rotor set consists of two rotors, a male and a female rotor, working in unison to create the necessary oil pressure and circulate oil effectively.

c) Relief Valve: A relief valve helps regulate oil pressure within safe limits. It opens when the pressure exceeds the designed threshold, allowing excess oil to return to the oil pan, preventing over-pressurization of the engine.

d) Housing: The oil pump is housed within the engine block or oil pan, ensuring proper alignment and connection to the engine's lubrication system.

4. Importance of Maintaining a Healthy Diesel Engine Oil Pump:

a) Performance: A well-maintained oil pump ensures efficient oil circulation, lubrication, and cooling, resulting in optimal engine performance and power output.

b) Longevity: Proper lubrication prevents premature wear and tear of engine components, extending the engine's lifespan.

c) Fuel Efficiency: Reduced friction due to proper lubrication maximizes fuel efficiency by lowering energy losses within the engine.

d) Reliability: A robust oil pump enhances the overall reliability of the diesel engine by minimizing the risk of component failures and costly repairs.

In summary, a diesel engine oil pump plays a critical role in maintaining the performance, longevity, and reliability of a diesel engine. Its primary functions include oil circulation, lubrication, cooling, and filtration. Understanding the importance of this vital component empowers individuals to maintain their engines properly, ensuring smooth operations and optimized performance.